What Makes Relativity Space’s Aeon Engines So Special?

Relativity Space is managing to make very promising progress in a short amount of time. This is the case despite the companies ambitious goals and plans for the future. Trying to create an entire rocket along with components such as the engine with 3D printing has its benefits along with many risks. However, if Relativity is capable of consistently creating and launching rockets with this technology they could save a lot of money and time.

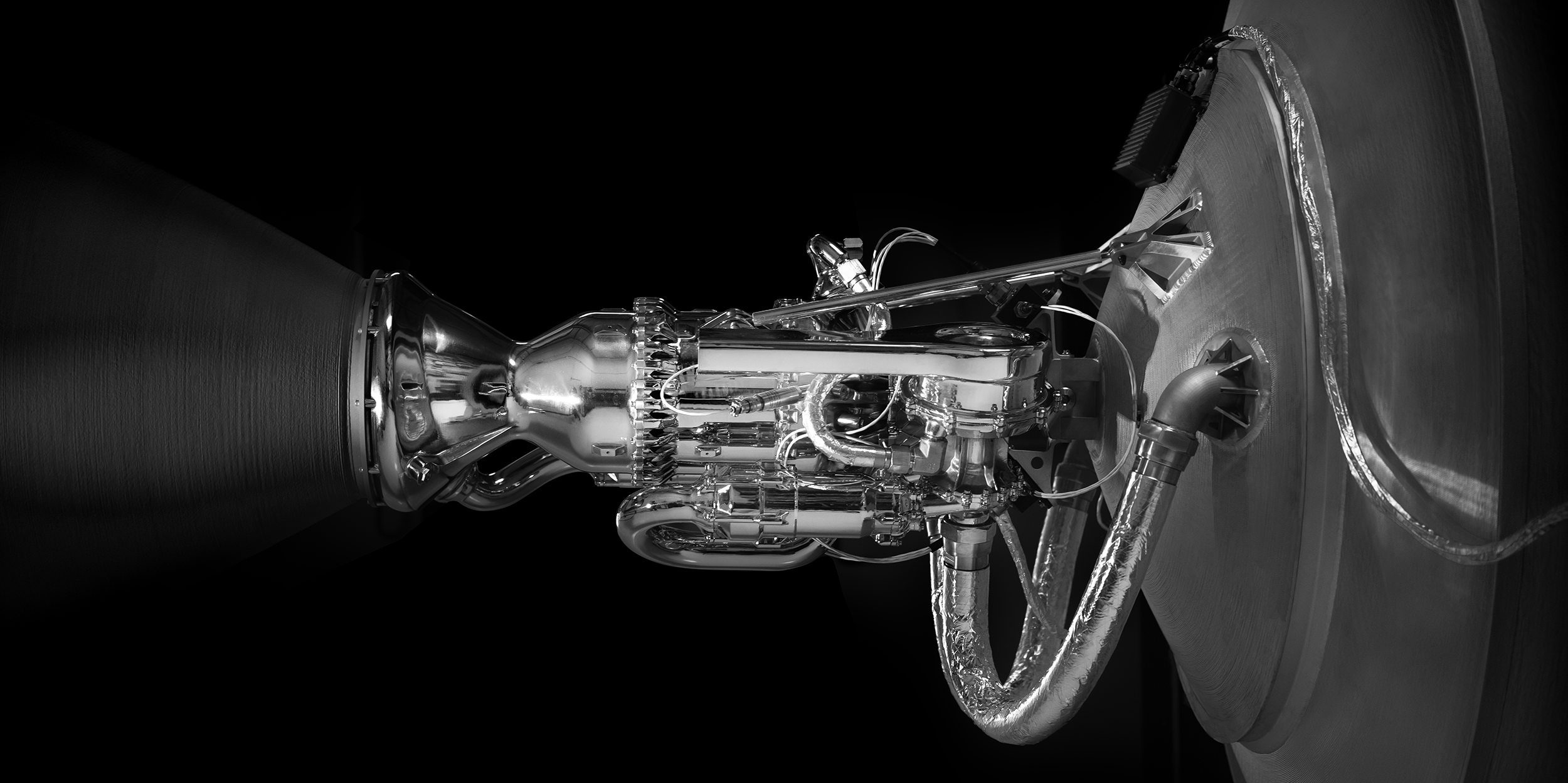

One of the most unique aspects of Relativity Space’s Rocket components is the Aeon Engines. These engines along with launch vehicles such as the Terran 1 use 3D printing to enhance mission reliability, lower costs, and improve efficiency. All of which are necessary for the future of the company and their success within the space industry and more. While this process is very difficult at first it could provide limitless benefits if designed in a reliable way.

Rocket engines are necessary pieces of technology that help propel a rocket and payload out of Earth’s atmosphere and to its destination. There is a lot more that goes into a rocket than just propellant and power output. In reality depending on the launch vehicle, mission, and much more, different factors need to be considered when developing and manufacturing the component.

Relativity Background

Relativity Space was founded in 2015 with the goal of expanding the possibilities for human experience. Their vision is a multi-planetary future that expands the possibilities for human experience and more. Specifically, the company’s long-term goal is to upgrade humanity’s industrial base on Earth and on Mars. They are trying to do this in a very unique way by fusing 3D printing, artificial intelligence, and autonomous robotics. In addition, the company mentions they are leading an unrivalled team to solve problems never solved before. This includes seasoned veterans and experts from the world’s most renowned aerospace, 3D printing, and technology companies working to revolutionize how rockets are built and flown.

Using unique technology such as the world’s largest 3D printers, Relativity is printing practically every single part of the rocket including the engines and much more. This helps reduce the number of parts and simplifies the process of manufacturing and building a rocket. This then provides faster design interactions and part optimizations, real-time quality control and part inspection, and sensor and analytics-driven machine learning. To put it in perspective, Relativity points out that other rockets often take a very long time to manufacture and host over 100,000 parts throughout the entire launch vehicle. Relativity on the other hand is able to reduce the parts to under 1000 by printing the engines, body, and more. They are able to d this thanks to proprietary materials designed for printing, AI controls, sensors, and analytics.

Aeon Engines

Currently, Relativity Space is working on and developing three engines named Aeon 1, Aeon R, and Aeon Vac. The Aeon 1 and Aeon Vac are smaller engines and are built for the company’s Terran 1 launch vehicle. The Aeon R on the other hand is bigger and used for Relativity’s future launch vehicle named Terran R. Relativity points out that these three engines are 3D printed, enhancing mission reliability by reducing part count in engine combustion chambers, igniters turbopumps, reaction control thrusters, and vehicle pressurization systems. In addition, all Aeon engines use propellants of the future such as liquid oxygen and liquid natural gas or LNG.

The reason for these propellants is not only because they are great for rocket propulsion but they are also the easiest to eventually make on Mars. Even with current launch vehicles and engine models, the company is thinking far ahead to extremely ambitious goals and more. These engines are designed, assembled, and tested in house. With the exception of the second-stage nozzle extension, each of Terran 1’s 10 engines is based on a common design enabling simplified and repeatable manufacturing and acceptance testing. All of the Aeon engines use the propellants I mentioned prior along with a gas generator engine cycle. Each engine uses two turbopump assemblies for thrust and mixture ratio control. Specifically, one for liquid natural gas and one for liquid oxygen. The thrust chamber is regeneratively cooled with LNG, which is then injected into the main combustion chamber and burned with liquid oxygen to produce the required thrust. Looking at the Aeon 1 and Aeon Vac, they are very similar with the exception of a larger nozzle on the Vac variant to help improve its performance in the vacuum of space.

Aeon Engines & Launch Vehicles

The Terran 1 uses two of Relativity Space’s engines they are currently developing and manufacturing. This is the Aeon 1 and Aeon Vac. In total there are 10 of these engines, 9 Aeon 1’s on the bottom of the first stage and a single Aeon Vac powering the second stage. These 9 Aeon engines power the first stage with up to 23,000 pounds of force per engine at sea level. This creates a total thrust of up to 207,000 pounds at liftoff. The Terran 1 autogenously pressurizes the tanks with gaseous natural gas and gaseous oxygen via heat exchangers integrated into the Aeon-1 engines. This eliminates the need for a separate pressurization system and avoids the use of helium on the vehicle entirely. Electromechanical actuators gimbal the outer 8 engines which provide thrust vector control. Looking at the second stage of the Terran 1, a single Aeon Vac propels it along with the payload on top. Specifically, this single-engine produces up to 28,300 pounds of force in a vacuum using a fixed 165 to 1 expansion nozzle.

This engine is capable of multiple restarts including provisions for deorbit burns which significantly increases its capabilities. Similar to the first stage, a heat exchanger on the Aeon Vac engine generates gaseous natural gas and gaseous oxygen that pressurize their respective tanks autogenously. Taking a look at the Terran R, there is a similar story in terms of engines. On the first stage of Terran R, it will also use a single Aeon Vac engine. The Terran R is meant to be fully reusable and far more powerful than Terran 1 with a 20,000 kg payload to LEO rather than 1,250 kg. This suggests that the Aeon R engine will not only be much bigger but a lot more powerful as well. With only 7 Aeon R engines on the bottom, they are expected to propel the entire rocket out of the atmosphere. Just like previous models, the Aeon R is planned to be 3D printed and built for a future surrounding Mars exploration and more. For this reason, the engine will likely use the same propellant as past models and not have too many differences.

Conclusion

Rockets are extremely complex pieces of technology and engineering that combine many different necessary components into a single launch vehicle. One of the most complex and important of these parts could be the engines. The rocket engines work to turn propellant into thrust in a very violent and important process. Without engines, a rocket would get nowhere off the ground. Relativity Space is working to change not only how we develop and manufacture rockets but engines as well. They are doing this with the help of 3D printing among other things to reduce cost, time, and simplify the design. Currently, the company is working on there different types of Aeon engines for two different launch vehicles. Relativity is making great progress but still has a long way to go ahead of them. We will have to hope for the company’s success along with the future performance of each of the Aeon engines.