An Update On Relativity Space’s 3D Printed Engines

There are many different components that go into creating a rocket and especially launch vehicles meant for the future of space travel. In addition to this, companies like Relativity Space are working to change not only how some of these parts operate but also how they are manufactured. This process has a lot of added risks and complications but if successful it could allow them to achieve great things.

In recent months as the company continues to work towards the first orbital test flight of Terran 1, they have been providing updates on the engines that will be responsible for accelerating the rocket. Specifically, people such as CEO Tim Ellis have been consistently providing pictures, videos, and context of what work is being done on the Aeon engine series and more.

All of which will play a vital role in the future of not only Terran 1, but also even more ambitious projects such as Terran R. Not to mention the fact that rocket engines are both equally important and complex. However, Relativity space is working hard and is confident in its design and manufacturing process. Here I will go more in-depth into some of the recent progress on the engines and what exactly makes them so special.

Recent Updates

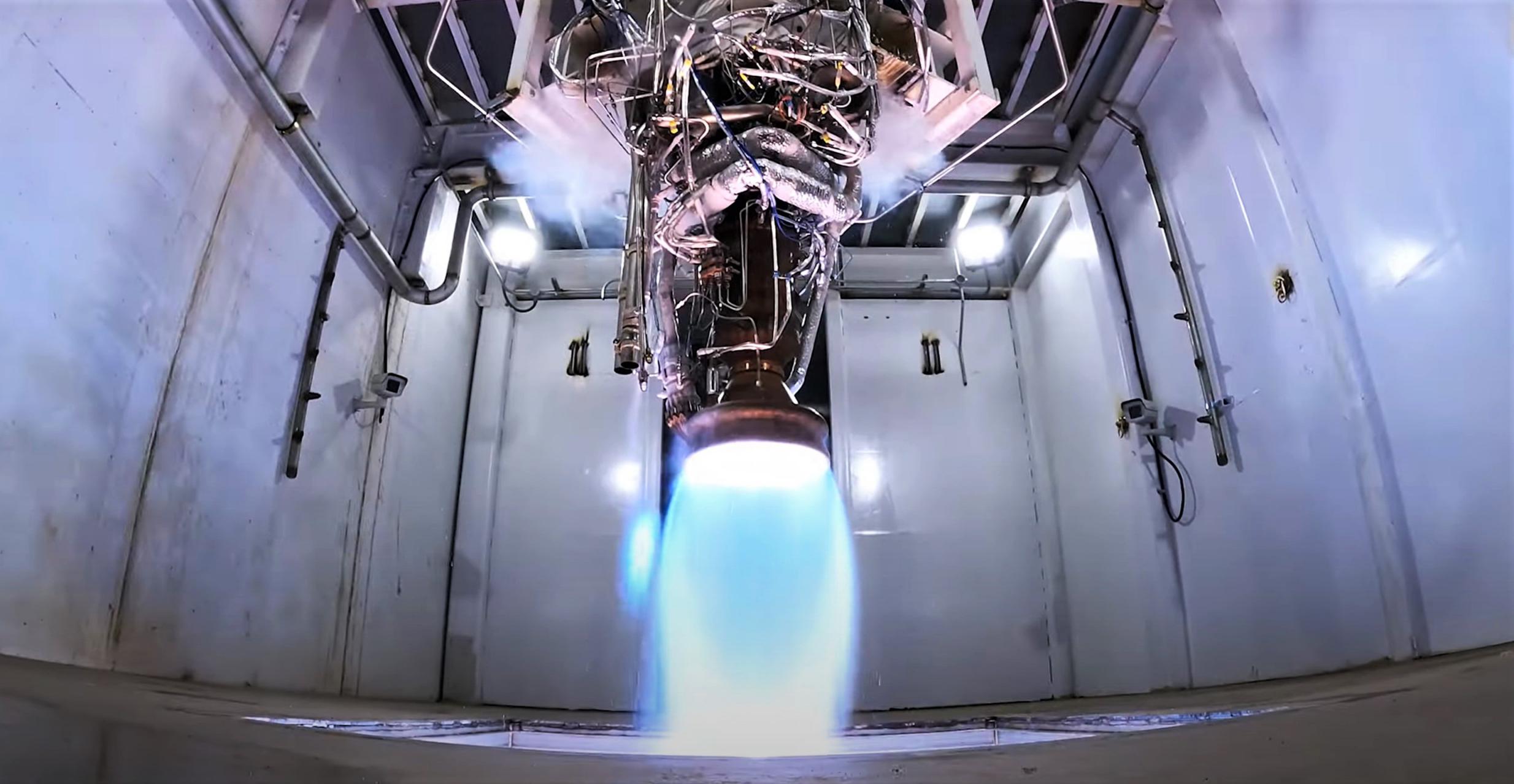

Relativity Space has been very busy in recent months working towards a first orbital test flight of Terran 1 along with the future of Terran R. This process includes a lot of time on the engines meant to be responsible for propelling these rockets of the future. Thankfully, CEO of Relativity Space recently provided a lot of updates on the company’s engine progress. Specifically, only a few days ago on May 9th, Tim Ellis tweeted saying, “We roll in improvements in almost every print iteration… this newer version of Aeon 1 has a larger expansion ratio nozzle and higher efficiency, just realized I don’t think we showed off publicly until now.” Relativity space often points out that one of the major benefits of its manufacturing process is the ability to rapidly iterate and improve with each print. This update is a great example and highlights the company actively using that process. Only one day later on May 10th, he provided even more updates. The first mentioned, “First turbopump housings for Aeon R are coming out lookin rad…again next to Aeon 1 for scale.” This tweet included a photo of both turbopump housing for both Aeon engines to highlight the significant difference in size. It also helps put in perspective the power difference expected for future launch vehicles.

Tim Ellis continued giving updates that same day as it seems Aeon R has made a lot of recent progress. Soon after the last update, he tweeted again, pointing out, “The main valve housings are coming along too, the team is doing an amazing job designing, building, and iterating as we push to first tests this year.” Here the picture shows the main valve housing which appears to have been manufactured very well. Next, he had even more updates saying, “Also finish machining our gas generator throttle body valves, these will help control our engine cycle and enable us to land Terran R with fine control of our main boost Aeon R engines.” Finally, the last update gave a great visual for both of Relativity Space’s engines and what to expect in the future. The tweet mentioned, “Ramping up printed Aeon R hardware and it’s HUGE vs Aeon 1. Fourth Aeon R full scale thrust chamber printed below, building to 52 full engines per year production rate by mid next year.” This tweet gives us quite a bit of information on the engines and future of Terran R. It not only points out the difference in size and expected power but also some of the goals Relativity Space has in terms of production rate. If they want to achieve some of the company’s ambitious goals it’s necessary for engine production to be a smooth and efficient process. We have seen recently with many other companies the issues that can come with engine production problems and more. However, due to Relativity Space’s unique manufacturing process, its possible they could secure a consistent future regarding rocket engines.

Aeon Engines

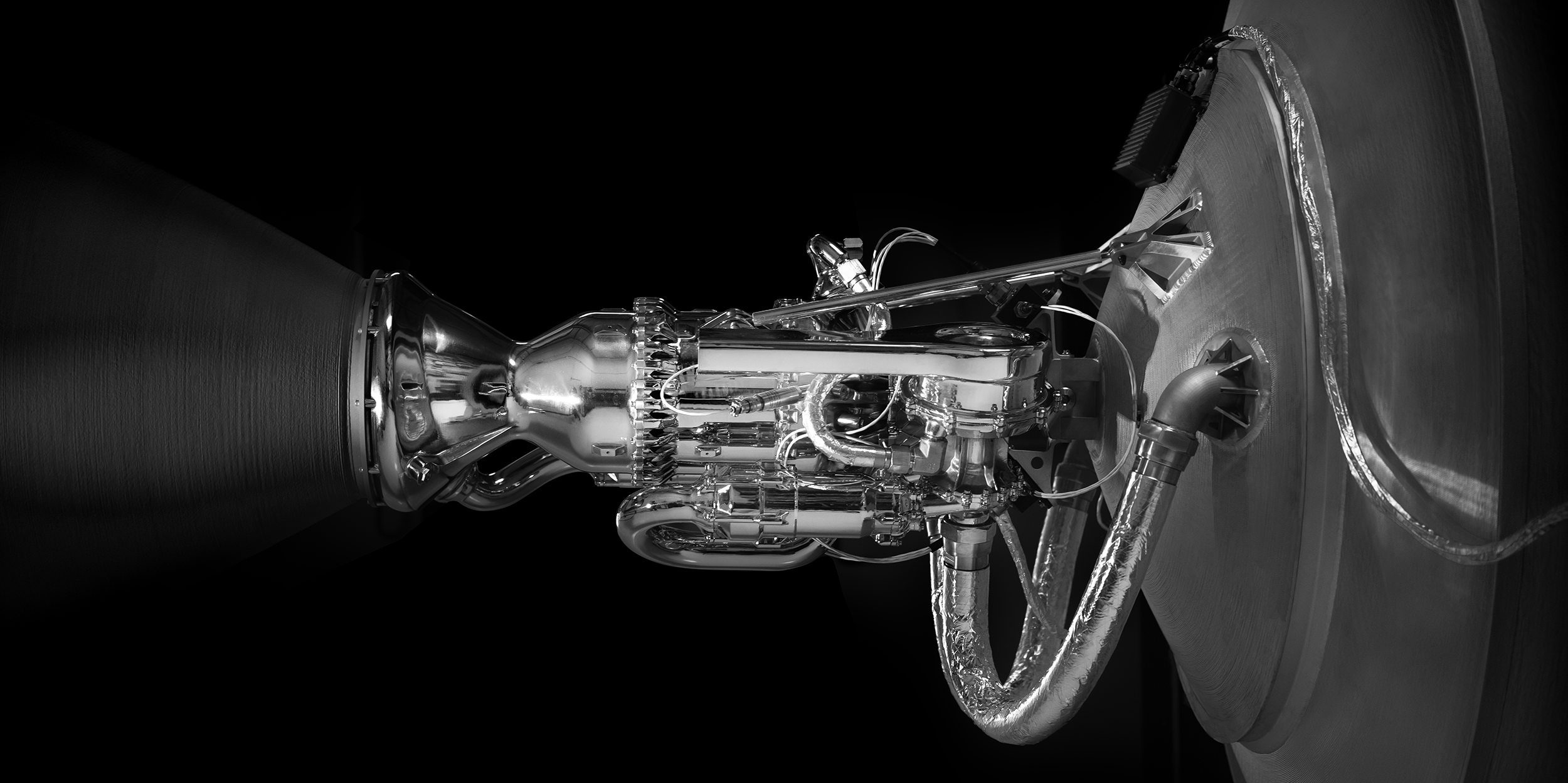

Now that we know more about some of the recent updates with both Aeon 1 and Aeon R, we can take a closer look at the engines themselves, their future use, and the manufacturing process in relation to these engines. As of right now, Relativity Space is working on three different Aeon engine variants. This includes Aeon 1, Aeon R, and Aeon Vac. Together these engines power each of the stages for both Terran 1 and Terran R. In terms of design, all of these engines are 3D-printed. Among other unique benefits, Relativity points out that this helps enhance mission reliability by reducing part count in engine combustion chambers, igniters, turbopumps, reaction control thrusters, and vehicle pressurization systems. In addition, all Aeon engines use propellants of the future such as liquid oxygen and liquid natural gas, which are not only the best for rocket propulsion, but also the easiest to eventually make on Mars. This being one of the company’s future goals is why it’s important to them. So far to date, Aeon has completed over 500 test fires in total.

Taking a more in-depth look, Relativity’s Aeon engines are designed, assembled and tested in house. Except for the second-stage nozzle extension, each of Terran 1’s 10 engines is based on a common design enabling simplified and repeatable manufacturing and acceptance testing. As mentioned prior, Aeon engines are fueled by liquid natural gas and liquid oxygen and operate using the gas generator engine cycle. Each engine uses two turbopump assemblies for thrust and mixture ratio control: one for liquid natural gas and one for liquid oxygen. The thrust chamber is regeneratively cooled with liquid natural gas, which is then injected into the main combustion chamber and burned with liquid oxygen to produce the required thrust.

These engines are very important as they provide thrust for both stages of both Terran 1 and R. Stating with the first stage of Terran 1, here nine Aeon-1 engines power the first stage with up to 23,000 lbf thrust per engine at sea level, for a total thrust of up to 207,000 lbf at liftoff. Terran 1 autogenously pressurizes the tanks with gaseous natural gas and gaseous oxygen via heat exchangers integrated into the Aeon-1 engines, eliminating the need for a separate pressurization system and avoiding the use of helium on the vehicle entirely. Electromechanical actuators gimbal the outer 8 engines, providing thrust vector control. Moving to the second stage, a single Aeon Vacuum engine powers the second stage with up to 28,300 lbf-vac using a fixed 165 to 1 expansion nozzle and is capable of multiple restarts including provisions for a deorbit burn. Similar to Stage 1, a heat exchanger on the AeonVac engine generates gaseous natural gas and gaseous oxygen that pressurize their respective tanks autogenously. We then have Terran R which is meant to be a much bigger and better version of Terran 1. The first stage will be powered by 7 Aeon R engines. These are the same engines that Tim Ellis recently provided many different updates on. From those examples earlier you can see how much bigger and more powerful they are expected to be. Relativity points out that these 7 engines alone will be able to produce 302,000 pounds of thrust each. This is quite the step up from the Aeon 1 engine and its capabilities.

Finally, Relativity points out the unique manufacturing process and the benefits it has not only on other components of the rocket but the engines as well. They highlight that For 60 years, aerospace manufacturing has relied on large factories, fixed tooling, complex supply chains, and extensive manual labor to build costly rockets comprised of 100,000 plus parts in 2 years or longer. To accelerate innovation in the industry, Relativity built its Factory of the Future, the first aerospace platform to automate rocket manufacturing, vertically integrating intelligent robotics, software, and data-driven 3D printing technology. Incorporating Stargate, the world’s largest metal 3D printer with AI-driven controls, Relativity’s Factory of the Future continuously optimizes production, resulting in greatly compounded quality and time improvements, lower costs, and product designs previously not possible. Relativity is an application-layer 3D printing company that is starting with rockets, and will extend its Factory of the Future to all of aerospace.

Conclusion

Rocket engines are equally important and complex pieces of equipment that all rockets need. Relativity Space is hard at work preparing for not only a first-ever orbital test flight with Terran 1 but also the development of the even bigger Terran R. These two rockets use Relativity Space’s in house engines including the Aeon 1, R, and Vac. Recently CEO Tim Ellis provided a bunch of updates on the progress and design of these engines. In order for the future of Relativity and its launch vehicles to go well, they will need to master the production process for all of these engines. We will have to wait and see how it progresses and the impact it has on the space industry.