A Closer Look At The James Webb Space Telescope’s Sunshield

Space telescopes provide a unique view of the universe’s past. The information gathered answers and brings up a long list of questions about everything including our own planet. The James Webb Space Telescope is set to be the most powerful and advanced telescope ever sent into space. It features many different fascinating components including a very large sunshield.

The James Webb Space Telescope has a large sunshield that keeps one-half of the telescope cold, this is necessary because the JWST observes infrared light. The shield does this by using 5 separate layers, Kapton material, and a unique shape and seaming. All work together to provide the telescope with a barrier from the constant heat emitted from the sun.

In total there are hundreds of components that make up the James Webb Space Telescope. All of which have to work perfectly once in space. This combined with the telescope’s orbit means that we can’t just send astronauts to go fix it. Additionally, with the telescope’s large size, many different parts need to be folded to fit in the fairings of the launch vehicle.

James Webb Space Telescope Background

The James Webb Space Telescope is a space-based observatory optimized for infrared wavelengths. The telescope has been in development for over 20 years and has cost NASA around $10 billion in total. The use of infrared light has a lot of different benefits and is meant to complement and expand on discoveries made by Hubble. Specifically, the JWST will cover longer wavelengths than Hubble and will have greatly improved sensitivity. The ability to view longer wavelengths allows the telescope to look farther back in time than ever before.

NASA expects to see some of the first galaxies ever formed when looking through the telescope. Additionally, space is full of large dust clouds that the infrared telescope will be capable of looking through, something not possible with Hubble. The telescope is planned to orbit the sun on a Lagrange point. This has to do with multiple factors including keeping the light from the Sun, Earth, and Moon protected by the sunshield. The James Webb Space Telescope is set to be one of the most complicated deployments after launch. The telescope has 178 release mechanisms each of which must operate flawlessly to complete the 40 or so major deployments. The launch has been delayed over time but is expected to launch on December 22nd, 2021.

Sunshield Features

5 Separate Layers – The first unique feature of the sunshield are the multiple layers. In total, the JWST has 5 separate layers that make up the sunshield. This unique design has a lot of different benefits starting with reducing the temperature. Each successive layer of the sunshield is cooler than the one below. Heat radiates out from between the layers and the vacuum between the layers provides a good insulator. If NASA were to use a single thick piece of material rather than separate layers, heat would conduct from the bottom to the top easier and faster. This is exactly what the James Webb Space Telescope is trying to avoid. Light first hits the bottom layer of the sunshield and starts to heat it up. Each layer blocks some heat and reflects the rest out the sides. By the time any heat has reached the final layer, there is practically nothing left and the telescope stays cool. The layers work together to reduce the temperature between the hot and cold sides by around 570 degrees Fahrenheit. Additionally, the layers are very thin and lightweight which is important for the development, launch, and deployment process.

Kapton Material – Another important aspect of the sunshield is the material it’s made out of and coated in. The five different layers are made from a material called Kapton. Each layer is coated in aluminum and the sun-facing side of the two hottest layers has an additional coating of treated silicon to help reflect the sun’s heat back into space. Taking a closer look at Kapton, it is a polyimide film that was developed in the late 1960s. The material was picked because of its very high heat resistance along with its stable characteristics. This means that the material can survive a wide range of different temperatures from minus 269 to plus 400 celsius. Even when reaching very high temperatures, the material does not melt. On Earth, Kapton is commonly used for electrical and electronic insulation applications. The layers coat in aluminum and doped-silicon is not only to help reflect heat but also optical properties and the shield’s longevity in the harsh space environment. The doping process is where a small amount of another material is mixed in during the Silicon coating process so that the coating is electrically conductive. The coating needs to be electrically conductive so that the Membranes can be electrically grounded to the rest of JWST and will not build up a static electric charge across their surface.

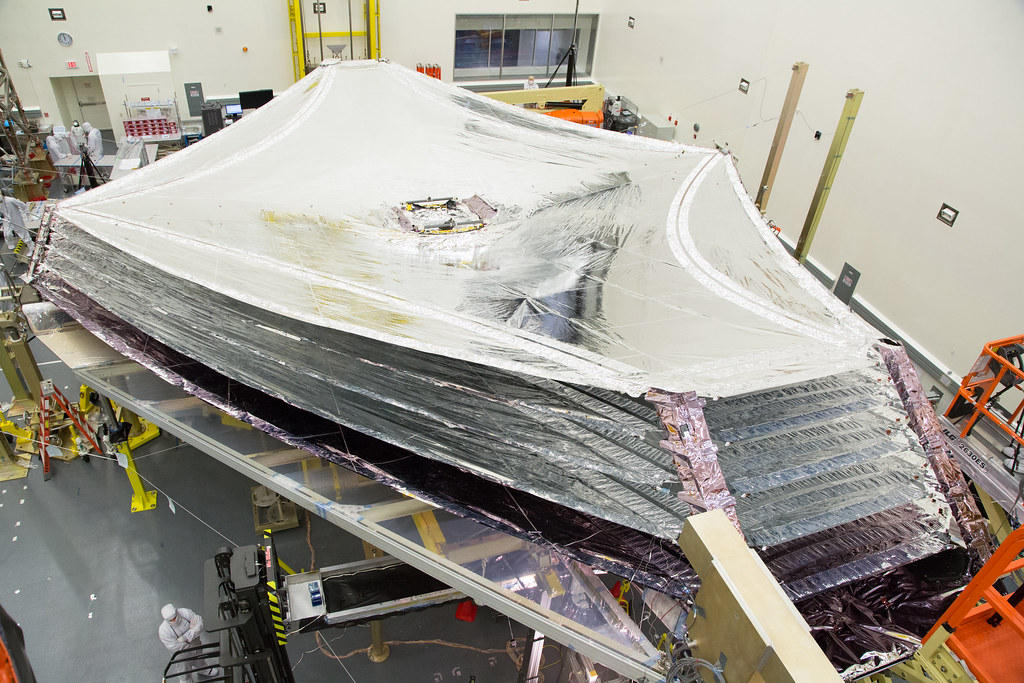

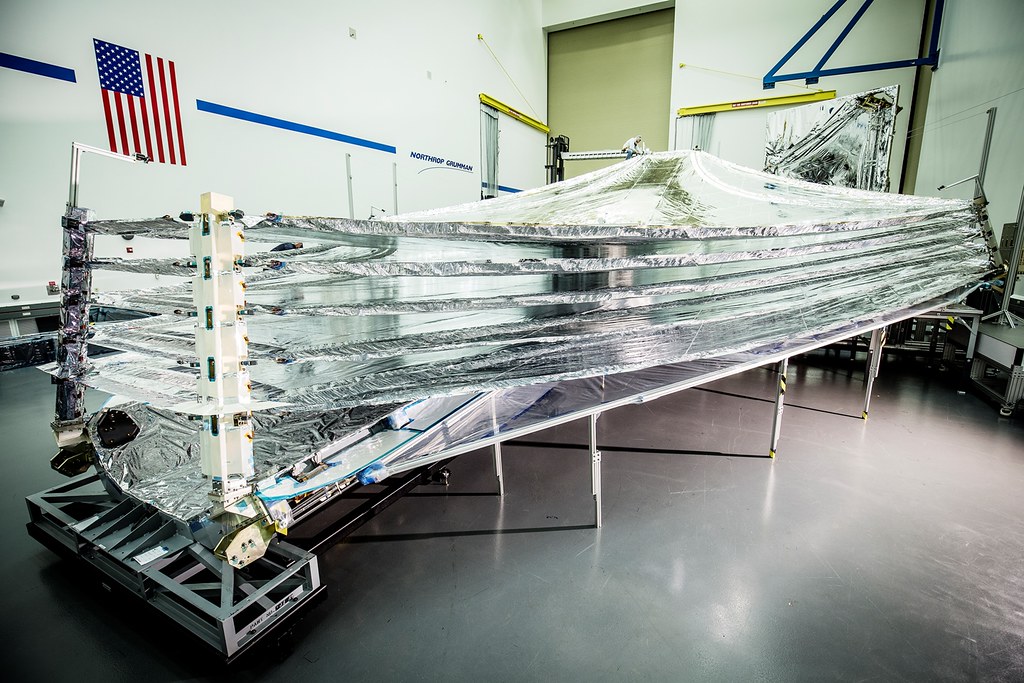

Shape & Seaming – The final feature of the sunshield that I wanted to mention was the shape and seaming. Starting with the very unique kite-like shape. There was a lot of thought that went into the shape of the sunshield and its effect on the telescope. The shape and design direct heat out the sides and away from the telescope. Specifically, heat generated by the spacecraft core is forced out between the membranes which avoids heating the telescope. The shape also works to fold and unfold which is necessary for the launch and deployment process. Then there is the unique seaming throughout the sunshield. The material used for the sunshield is very tough, however, if a small hole was to form, it could easily get bigger over time and become a large problem. To solve this issue, the material uses a special process called a Thermal Spot Bond. This is where many different areas of the material are melted together. In addition, reinforcing strips of membrane material are Thermal Spot Bonded to the parent membrane about every 6 feet or so, forming a grid pattern of “rip-stops.” In tests, this has been shown to stop tears from expanding past a given grid area.

Sunshield Deployment

As I mentioned prior, because of the James Webb Space Telescopes’ large size, many different parts and components of the telescope need to be folded up for launch. Once in space, the telescope will unfold and deploy many different parts over the course of multiple days. One of the biggest parts of the JWST is the sunshield. The sunshield is about 22 by 10 meters in size. This makes the deployment process very unique and complicated. The sunshield component attaches to the primary spacecraft in the center. For deployment, multiple boom arms extend outward bringing and expanding the sunshield as well. This is a very complex and careful deployment because of the importance and large number of moving parts. NASA has tested this process many times to ensure it works once in space.

Conclusion

The James Webb Space Telescope is set to be the most powerful and complex telescope ever sent into space. If successful, it will provide one-of-a-kind information that allows us to look into the past of the universe. The telescope is very complex and uses a large sunshield to keep the main telescope instruments cold. The sunshield does this using 5 separate layers, Kapton material, and a unique shape and seaming. All work together to reflect and distribute heat back into space and away from the infrared telescope. The launch is planned to happen within a month on December 22nd, 2021. We will have to wait and see the launch and deployment process along with the incredible information it provides.