Rocket Lab’s Electron Payload and Launch Operations

A rocket launch is an extremely fascinating and complicated process. This consists of many different specific challenges and goals that all need to be perfect in order for the mission to be a success. Rocket Lab and the Electron launch vehicle provide great examples of this when different customers purchase a spot on top of Electron. Here Rocket Lab has very thorough and in-depth operations for this specific task.

Rocket Lab over time has developed quality operations for both payload and launch of the Electron rocket. This consists of specific facility layouts, payload processing flow, transportation, an in-depth schedule, and more. All of which help make what can be an overwhelming process into a smooth and successful launch. Important for both Rocket Lab and customers picking a launch provider.

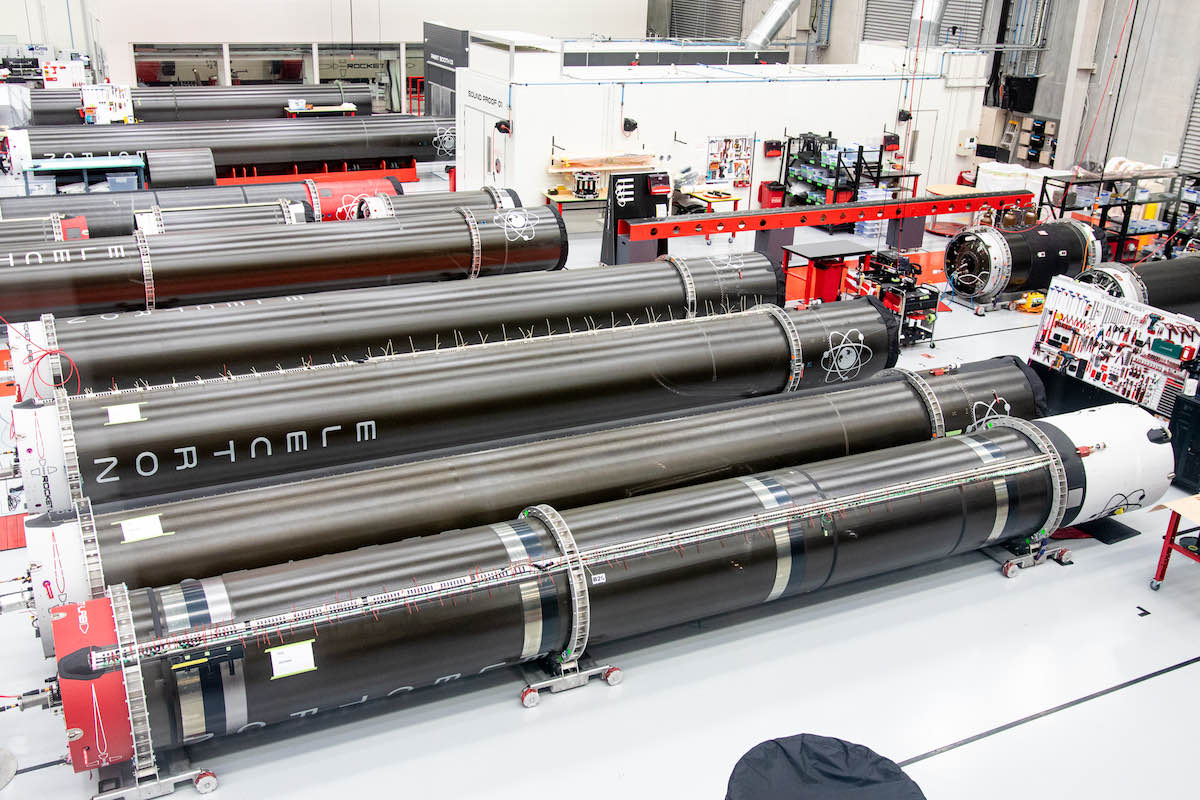

For quite a while now Rocket Lab has been consistently launching their Electron rocket. This has helped the company achieve an impressive 100 plus successful satellites launched with Electron alone. A big part of this success comes down to not only the design of the rocket but the behind-the-scenes work as well. Here I will go more in-depth into that process and exactly what it entails.

Payload & Launch Operations Background

One of the biggest purposes of payload and launch operations comes down to simplifying the process and making it much more appealing to customers. Rocket Lab highlights that its process is simple, seamless, and tailored to your mission. Specifically, payload integration and launch operations have been designed to be as easy as possible. This process focuses on the typical processing flow of standard Electron missions from Rocket Lab’s two launches sites consisting of Launch Complex 1 and Launch Complex 2. Rocket Lab can tailor standard payload processing and launch procedures to specific mission requirements as needed. The more options and flexibility Rocket Lab offers, the more appealing picking them as a launch provider becomes. Customers have the choice of processing their payload at Rocket Lab’s state-of-the-art payload processing facility at Launch Complex 1. In addition to this option, they can also choose either of the two Rocket Lab payload processing facilities in development in California and Virginia. These facilities include ISO 8 cleanrooms, dedicated electrical control rooms, and comfortable customer lounge-style offices. Rocket Lab has done everything in its power to try and make this process not only streamlined but enjoyable as well.

Specific Operations For Electron

Payload Processing Flow – One of the first important aspects of what could be considered behind-the-scenes work, involves the payload processing workflow and steps. Rocket Lab believes the payload processing flow should be simple, seamless, and tailored to each customer’s specific mission. This is why the company gives customers a choice of integration locations. The Rocket Lab integration team works closely with its customers on all missions, providing support every step of the way. Starting with the first step of spacecraft delivery to the preferred payload processing facility. Spacecraft delivery typically occurs 30 days prior to launch, however, this timeline can be adapted to specific mission requirements. Once received, Rocket Lab supports customers with unpacking the spacecraft and associated ground checkout equipment. Next is the spacecraft processing. Customers complete independent verification of the spacecraft, perform final tests, and carry out final preparations such as battery charging, software loading, and power-ups. Then there is the spacecraft integration.

At this point, the spacecraft is mated to the separation system or payload plate. For customers integrating in Long Beach, the spacecraft can be transported to the launch site mated to the payload plate. The other option can be for the final mate to occur once the spacecraft has arrived at the launch site. After the spacecraft integration, you have the fairing encapsulation. The integrated spacecraft and separation system on the payload plate that is mated with the kick stage is then encapsulated within Electron’s payload fairing. Encapsulation occurs horizontally, however, the fairing is raised vertically in the cleanroom for a vertical check. Lastly, you have the final mate with the Electron launch vehicle. Rocket Lab horizontally mates the encapsulated payload assembly to the launch vehicle ahead of wet dress rehearsal and launch. It even is possible to allow late access to the payload for mission-critical needs on request. Additionally, it is possible for spacecraft to be stored securely at Rocket Lab facilities in a flight-ready state for responsive launch on demand.

Facility Layouts – Another important aspect of payload processing has to do with the layout of different facilities and launch complexes. The payload processing facility at Launch Complex 1 includes dual customer spacecraft processing areas consisting of a single airlock, dual cleanrooms and owning rooms, and two separate client areas adjacent to the cleanrooms. The client rooms provide the customer with connectivity to their payload and a comfortable work area with desk space, sofas, internet connectivity, and power outlets.

Moving to the launch process Rocket Lab made sure to factor in the customer again. For missions lifting-off from Launch Complex 1, Rocket Lab also offers a Customer Launch Experience Room or CLER located at the Range Control Center around 2.5 kilometers from the launch pad. The CLER is a comfortable private facility that provides Rocket Lab’s customers with panoramic views of the launch pad, enabling them to experience an unrivaled lift-off. Then there is HQ in California. The Long Beach Payload Processing Facility at Rocket Lab Headquarters in California currently includes a gowning room and an ISO 8 class 100,000 cleanroom. Construction is underway on new cleanroom facilities at this location to mirror those available at Launch Complex 1. The new cleanroom facilities will be available for customer use in mid-2021.

Transportation & Schedule – One last key feature of the payload and launch operations focuses on the transportation and schedule. Starting with transportation, payload shipment to the launch site is to arrive no later than 30 days prior to launch. Depending on customer preference, payloads can either be integrated and prepared for shipment in Rocket Lab’s Long Beach, California cleanroom facility, or can be shipped directly to the launch site and integrated in the Payload Processing Facility or PPF at Launch Complex 1. All payloads will arrive in Auckland, New Zealand to clear customs, they then will be transported by ground or by air to the PPF at Launch Complex 1. Rocket Lab can arrange transportation between Auckland and Mahia as an additional service if requested. In the case of rideshare missions, CubeSats will typically be integrated to their dispensers at Long Beach approximately 40 days prior to launch. Upon arrival at the PPF, the payload is immediately unloaded and transferred to the cleanroom. Lastly Rocket Lab provides a graphic showing an in-depth view of the launch operations schedule. They point out that timelines can be altered upon customer request if necessary.

Conclusion

Rocket launches are a very extensive process with the majority of the work happening prior to the launch itself. Behind the scenes, an immense amount is happening to ensure everything goes perfectly on the launch day. Companies including Rocket Lab work to not only make this process simple but also as easy as possible for whichever customer. They do this with a seamless, payload processing flow, facility layouts, and transportation and schedule. All of which are necessary pieces within the big puzzle of launching a rocket and payload successfully. It is obvious through Rocket Lab’s record they have a good system in place for these operations. With many more launches planned for the future, we will have to wait and see Rocket Lab’s progress and the impact it has on the space industry.