Pangea Aerospace’s Revolutionary Work On Aerospike Engines

Rocket engines are one of the most complicated components of an entire rocket. Not to mention their importance for launching and propelling the rocket along with its cargo to whatever destination. There are many different styles and types of engines with different sizes, shapes, propellants, and much more. Each ends up impacting cost, efficiency, and additional important factors.

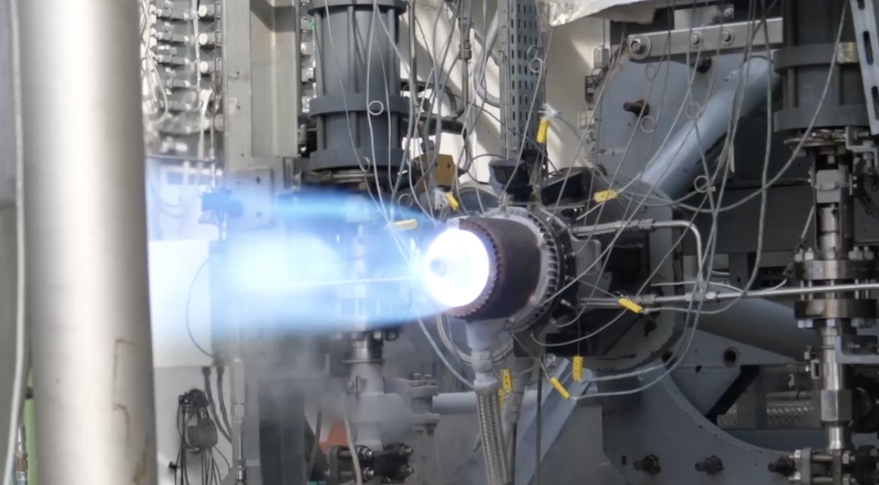

Pangea Aerospace is a smaller company working on an aerospike engine. While not a new concept, there are many different challenges and benefits of using this design. The company is working to solve these issues by making the engine cheaper, more efficient, smaller, and more. All of which are combined into a rocket engine development program that could end up changing the future of propelling rockets.

Take a look at practically any launch vehicle right now and you will likely see a bell nozzle engine. These are the most common, tested, and practical engine types out there. However, the bell nozzle is not perfect and is not the only option. While agencies and companies have experimented with aerospike engines for quite a while, many have failed to develop a quality and practical product. Pangea Aerospace is working on changing this.

Pangea Aerospace Background

Pangea Aerospace is a new company that was founded a few years ago in 2018. They are working on unique and advanced technology including aerospike engines, a next-generation launch vehicle named MESO, and rocket recovery technology. However, many of these different projects are focused on the use and development of aerospike engines. Pangea Aerospace’s goal is to unlock the untapped potential of new technologies that will drastically reduce the cost of launch. Specifically, they mention they are developing the most efficient and modern rocket engines to tackle the challenges of a transforming space industry.

Pangea Aerospace even advertises to take advantage of their expertise in aerospike nozzles and additive manufacturing to maximize the payload capacity of your launch vehicle and to decrease your manufacturing and operational costs. Pangea Aerospace’s planned future launch vehicle design is powered by a single large aerospike engine on the first stage. The company is very confident in its technology and the future of aerospike engines despite past challenges. One of the reasons for the company’s increased success has to do with advances in technology including 3D printing and other manufacturing features. The team at Pangea Aerospace consists of European aerospace engineers that strive to create the technology of the next generation of launch vehicles.

Aerospike Engine Features

Cost – One of the first important aspects of Pangea Aerospace’s work on aerospike engines is the cost. Rocket engines have always and continue to be extremely expensive. This is the case whether you are using a bell nozzle or aerospike engine. However, aerospike engines have some additional costs due to the long list of complications with development, manufacturing, etc. Pangea Aerospace however is confident they have lowered the cost significantly for primarily the manufacturing cost. Specifically, they mention the engines are additively manufactured in only two pieces which reduce the cost to a fraction of what it normally costs.

The reduction in parts simplifies the manufacturing process a lot which has a direct impact on how much the company pays to build and assemble an aerospike engine. Taking a look at the engines in space performance compared to cost, Pangea Aerospace shares a similar story. The company points out that their aerospike engine provides a low-cost propulsion system in relation to in-space performance. Cost can often be one of the limiting factors of any component or project a company or agency starts to develop. If Pangea Aerospace can continue to lower the cost and simplify the design, it’s possible they make aerospike engines a lot cheaper and more appealing.

Efficiency – The next key feature in their development of aerospike engines involves efficiency. When creating a rocket engine, you often are balancing a lot of different features of the engine. This includes the size, power, propellant, etc. Often times companies or agencies create engines and don’t push them to their max for multiple reasons. This could be to keep the engine in good quality, continue to reuse it, and more. All of these are factors that are considered when developing, manufacturing, and testing a rocket engine. Pangea Aerospace has been hard at work on the efficiency of aerospike engines and how they can improve each aspect.

The company mentions that the holy grail of rocket engines is now a reality thanks to their proprietary designs, new copper alloys, and additive manufacturing. Specifically, they mention that their aerospike engines are up to 15% more efficient. This allows a much higher payload capacity for the launch vehicle being powered by these engines. Pangea Aerospace includes that the engine shares its major structural elements with the launch vehicle which reduces the weight and helps with efficiency. Lastly, these engines are built with the most advanced copper alloy and regeneratively cooled using both propellants LOX and LCH4, helping improve the performance.

Size & Other Features – The final aspects of Pangea Aerospace’s aerospike engine development I want to mention are the size along with other features. The size of an engine obviously plays an important role. Depending on the size you can increase and decrease power along with impacting the number of engines on a launch vehicle. Pangea Aerospace points out they have improved the size of aerospike engines by creating a smaller nozzle for the same thrust level. Another benefit has to do with throttling capabilities. They mention their aerospike engines have throttling capabilities making them an interesting candidate for lander missions.

Rocket engines often struggle to control exactly how much power they are producing. This especially is the case when trying to lower the amount of power the engine produces. The ability to control this when landing a rocket can facilitate a smooth landing using only a single-engine. Another important aspect is reusability. Pangea Aerospace says its engines are designed to be reusable at least 10 times along with internal sensors in place to monitor the system in real-time. Lastly, the company points out the engines are simple and light, reinstating the engines are only manufactured in two pieces thanks to their proprietary design. The engines use green propellants consisting of liquid oxygen and liquid methane. Pangea Aerospace is confident saying they have solved problems that are historically associated with aerospike engines including cooling, weight, and manufacturing costs. While they have made some progress, there is still a long way to go. The company is very confident but there are a lot of reasons why aerospike engines are practically never used. However, any progress is good and we will have to see what Pangea Aerospace is capable of creating.

Conclusion

Rocket engines are not only extremely complex but important as well. Companies and agencies have continued to upgrade and change engines to increase efficiency, lower cost, and more. They do this by changing the size, style, and in this case, the nozzle. While the bell nozzle is the most popular option, companies such as Pangea Aerospace are trying to change that and improve the aerospike engine. They are doing this by lowering cost, increasing efficiency, and improving the size along with other features. While the company is confident, they still have many challenges ahead of them. They have made some progress and have big plans for the future including a rocket primarily powered by a single large aerospike engine. We will have to wait and see how the company’s development continues and the impact it has on the future space industry.