Is Blue Origin Making Progress On The BE-4 Engine?

Over the past few years, many of us have been keeping track of Blue Origin and the company’s progress on its BE-4 engine. This is for a variety of reasons including the future launch vehicles that depend on it including New Glenn and Vulcan, to name a few. However, Blue Origin’s development and manufacturing of this engine has not gone extremely smoothly over time.

This being said, it seems the company is making impressive progress on the engines and working towards a brighter future. Only a few days ago Blue Origin provided a few updates regarding BE-4 and the impressive results it has shown. This is in addition to updates from Tory Bruno who has been waiting for these engines for quite a while.

A rocket engine is an immensely complex and important piece of equipment that any rocket relies on. This is part of the reason why the BE-4 engines have received so much attention through the years. Blue Origin may have hit some bumps throughout this engine’s life but they continue to progress and improve the design. Here I will go more in-depth into the recent updates from Blue Origin and Tory Bruno, along with what to expect regarding the BE-4 engine.

Recent Updates

Blue Origin has been working on the BE-4 engine for quite a while now. This process has had its ups and downs and continued to make progress no matter how slow or fast. Over these past few years, delays had been accruing in the program, including turbopump problems, combustion instability, overheating, and a shorter than planned engine life, just to name a few. In addition, company management issues in the past left insufficient hardware to build development engines, leading to extended periods where no testing could be done. These among other issues have continued to delay the completion and release of these next-generation rocket engines. However, recently it seems the company has been making big strides with the engines. This is great news for not only Blue Origin as multiple future launch vehicles rely on these engines. One of the first updates was provided just over a week ago in late April. Specifically, on April 26th, Tory Bruno, CEO of ULA, tweeted saying, “Engines!! Vulcan Flight BE-4s heading to the build stand.” This tweet accompanied a photo of three different BE-4 engines. Tory clarified that these two engines featured the main combustion chamber and nozzle, while some of the other necessary components like the turbopump are in assembly. In the image, you can also see a third more complete BE-4 engine in the background. In the replies of this tweet someone said the engines likely don’t work. Tory replied mentioning, “Nope. The engine completed before these did many thousands of seconds of hot fire time, across the full throttle range and run box (and then some), a Vulcan duty cycle, and dozens of starts. Performance better than expected.” It’s clear that Tory is happy to finally be receiving some engines as the progress on Vulcan continues at fast speeds.

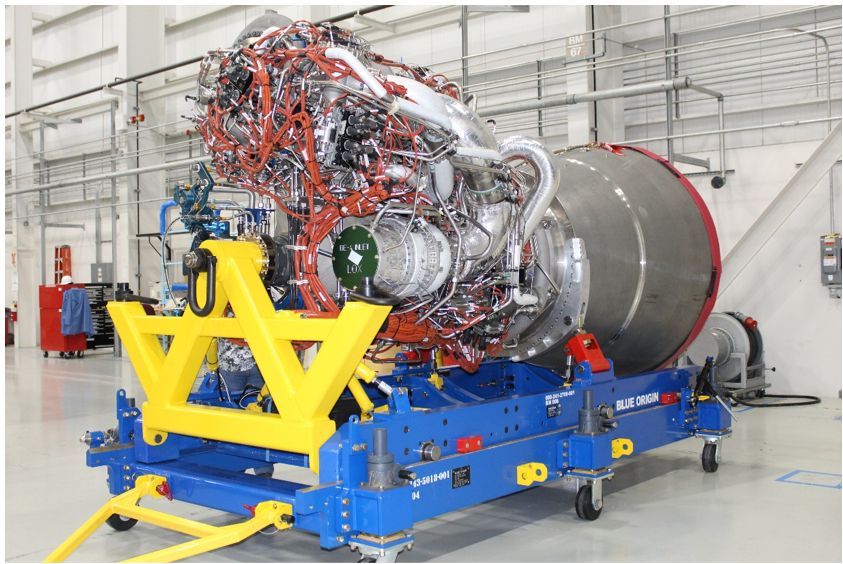

However, these tweets from Tory Bruno were not the only updates on BE-4’s progress. Blue Origin also gave a few updates on the engine. Specifically, only a few days ago on May 2nd, Blue Origin tweeted saying, “We extensively tested flight-configuration engines up to and beyond the entire operating envelope, delivering superior performance (specific impulse, thrust) for an LNG engine. Thanks to learnings from these test series, we are confident in our first flight engines.” This tweet featured a photo of a BE-4 engine in Blue Origin’s facility. The next update came later in the same day and mentioned, “PQE-802 characterized unit to unit variation in the different flight-configuration builds. This engine configuration achieved sustained 104% power level operation (572,000 lbf thrust).” Here you could see a large group of Blue Origin employees standing in front of BE-4. The company continued to provide updates on the engine with another tweet the same day. This one said, “PQE-602 was the first of Blue Origin’s flight-configuration BE-4 engines that we assembled and tested, achieving consistent and repeated mission duty cycle hotfires for over 2,500 seconds of test.” The tweet featured an up close picture of BE-4 on the test stand. Finally, the next day on May 3rd, Blue Origin provided a final tweet pointing out, “Earlier this year, a BE-4 flight-configuration engine gimballed 8 degrees while operating at 100% power level.” The attached GIF showed the engine firing in a few different degrees. This will be necessary if Blue Origin wants to successfully land New Glenn on a ship in the ocean after launch.

As we know, both New Glenn and ULA’s Vulcan need these engines in order to progress and launch in the future. As time goes on the pressure continues due to the progress companies like United Launch Alliance are making. Just a few days ago Tory gave a few updates on Vulcan with pictures of the launch vehicle and its fancy paint job. The Vulcan’s booster is powered by a pair of BE-4 engines producing over half a million pounds of thrust. We have seen ULA continue to make impressive progress with this vehicle and the need for BE-4 engines is higher than ever. In terms of New Glenn, the development has not been nearly as fast. This being said the rocket will use 7 BE-4 engines on the booster capable of launching and landing the first stage.

BE-4 Overview

Now that we know some of the recent news regarding BE-4, we can take a closer look at the engine itself and what it’s expected to provide. Blue Origin describes it as America’s next rocket engine. The first oxygen-rich staged combustion engine made in the U.S. meant to power two vehicles in the next generation of American orbital rockets. BE-4 is expected to be the most powerful liquefied natural gas (LNG) fueled rocket engine ever developed. Using an oxygen-rich staged combustion cycle, BE-4 is capable of producing 2,400 kN or 550,000 pounds of thrust with deep throttle capability. They point out that they chose LNG because it is highly efficient, low cost, and widely available. Unlike kerosene, LNG can be used to self-pressurize its tank. Known as autogenous repressurization, this eliminates the need for costly and complex systems that draw on Earth’s scarce helium reserves. LNG also possesses clean combustion characteristics even at low throttle, simplifying engine reuse compared to kerosene fuels.

Overall, BE-4 was designed from the beginning to be a medium-performing version of a high-performance architecture. It’s a conscious design choice made to lower development risk while meeting performance, schedule and reusability requirements. With Blue Origin’s hardware-rich approach, multiple developmental units and redundant test stands enable a high test tempo and rapid learning. In terms of production, BE-4 is currently undergoing full-scale engine development testing at Blue Origin’s facilities in Van Horn, Texas. Full rate production will occur in their new engine manufacturing facility in Huntsville, Alabama.

As partially mentioned prior, seven BE-4 engines will power New Glenn’s reusable booster, and two BE-4 engines will drive the first stage of United Launch Alliance’s Vulcan launch vehicle. For quite a while now both companies have planned to use these engines in their next-generation launch vehicles. New Glenn’s fully reusable first stage is designed for a minimum of 25 flights, making it competitive for a variety of launch markets. Civil, commercial, and national security customers can all find solutions in New Glenn’s high-performance configuration. In addition to this, Blue Origin is trying to make New Glenn a reliable, cost-competitive system with high availability. The 7-meter fairing has two times the payload volume of any existing launch vehicle, which means more room for satellites and the freedom to build in more capacity. New Glenn is also able to launch and land in 95% of weather conditions, making it a reliable option for payload customers. For Vulcan, ULA is leveraging the proven processes, technology, and expertise of Atlas and Delta. The Vulcan Centaur rocket introduces new technologies and innovative features to create the highest value launch service with optimal performance to meet the full range of mission requirements. Vulcan Centaur consists of a single booster stage powered by a pair of BE-4 engines, the high-energy Centaur upper stage powered by two RL10 engines and a 5.4-meter-diameter payload fairing. Lastly, for additional power at liftoff, up to six solid rocket boosters can be added to the Vulcan Centaur rocket.

Conclusion

A rocket engine is both an immensely complex and important component of any launch vehicle. This especially is the case for next generation rockets such as New Glenn and Vulcan. Over the life of BE-4, the engine has not had the smoothest development. This being said Blue Origin has progressed through the multiple complications and delays and are making progress on it. This is increasingly important as New Glenn and especially Vulcan get closer to completion. We will have to wait and see how it progresses and the impact it has on the space industry.