Astra’s Progress, Spacecraft Engines & Recent Contract With LeoStella

Recently Astra managed to successfully launch a rocket to orbit and deliver the payload. This was a massive milestone for the company after multiple previous launch attempts did not go according to plan. However, in addition to this recent success, the company has been continuing to develop and innovate in other ways.

Specifically, only a few days ago, Astra announced they had signed a significant contract with LeoStella LLC for Astra Spacecraft Engines. These engines are meant to help LeoStella continue to deliver constellations into orbit and beyond. In addition, Astra has been making significant progress on rocket development, testing, and launch procedures. This all plays into the success of the company and the future of Astra’s opportunities.

There are many different aspects of rockets and satellites that are necessary, however, engines are easily some of the most important. When used for spacecraft and satellites, they have many jobs including keeping the payload in orbit along with ensuring it’s in the exact spot it’s supposed to be. Here I will go more in-depth into Astra’s recent contract and the company’s spacecraft engines.

Astra’s Progress

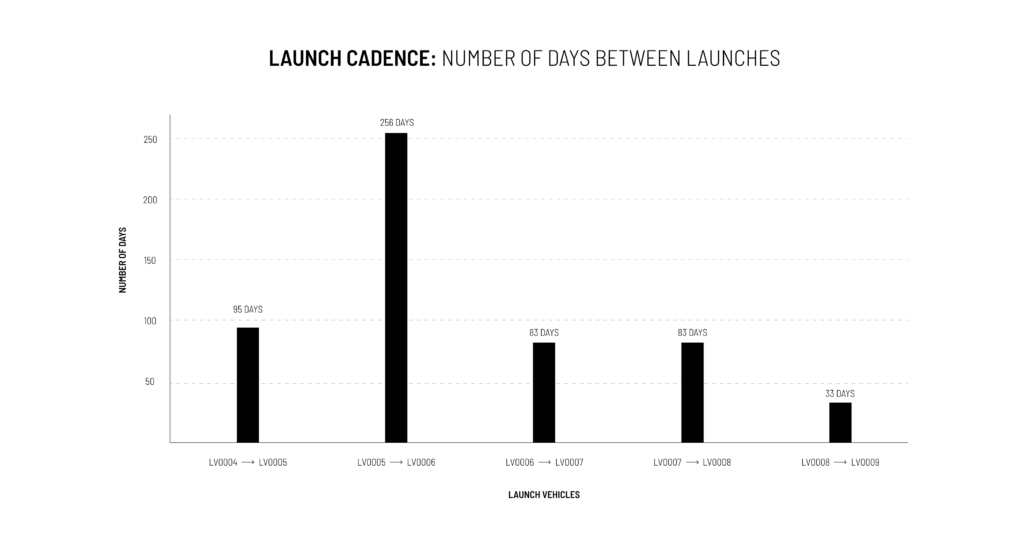

Astra Space has managed to prove itself as a fast pace and ambitious company working to offer a large list of services for the space industry. As the demand for launch services and more continues to grow, Astra like many other companies is expanding its operations. First looking at the company’s progress, earlier in the month Astra tweeted saying, “VP of Operations Bryson Gentile shares operational progress leading up to @SpaceflightInc’s Astra-1 mission.” Here, Astra provided information on past launches and general operations and the improvements the company has made in such as short period of time. Specifically, they first highlight the launch cadence over the past few years. Launch cadence is the ultimate measurement that enables Astra to deliver to its customers. They have been working toward decreasing the number of days between launches and they plan to continue this trend in the right direction. Notably, between LV0008 and LV0009, Astra completed its LV0008 investigation incorporated corrective actions into LV0009, tested the updates, and returned to the launch pad to commence operations for this mission. They also provide a chart that shows the time between launches going all the way back to LV0004. One aspect that stands out is that the turnaround time for LV0006 is longer than the others. Astra explains that this is the case due to a large number of upgrades that were made to the launch vehicle during that time. The other main aspect of the chart you will notice is the improvement in time between launches each year. For example between LV0004 and LV0005, it took 95 days. Compare this to the recent launches of LV0008 and LV0009 with only 33 days in between.

The next important aspect of improvement has to do with the build rate. This is the cadence, or takt, at which Astra delivers new rockets out of the factory. They are currently producing a rocket a month, and aim to increase this cadence this calendar year. Operating in continuous production means that Astra usually has an upcoming vehicle in stock or in transit while they are launching one on the pad. By the time they launched LV0008, LV0009 had already shipped to Kodiak. After the launch of LV0008, Astra was able to return LV0009 to the factory to make repairs identified from the LV0008 anomaly. Having a complete rocket on hand was a tremendous asset towards finding the root cause of LV0008’s anomaly. Astra’s team was able to quickly validate its corrective actions against real flight hardware before shipping LV0009 again a few weeks later, demonstrating the company’s ability to rapidly iterate and improve with every launch vehicle iteration. Here Astra provides another chart that highlights the improvement made over the past few years and where the company is at now.

The last major improvements the company has made has to do with campaign length and countdowns per launch. Starting with campaign length, after arriving in Kodiak with LV0009, Astra set up its launch system and completed tests and checkouts on site. They aim to static fire test, launch, and then safe the site and pack the site back into shipping containers within three weeks. A campaign without site setup and teardown in between has the potential to be even faster. Just like the other metrics, campaign length has improved significantly over the past few years and launch vehicles. Lastly, you have countdowns per launch. Astra has now had two vehicles in a row, (LV0008 and LV0009) that lifted off in the first minute of the launch window, demonstrating a well-timed, repeatable operation that they plan to continue. The duration of the campaign for LV0007 taught Astra a lot of great lessons about how to design for operating in strenuous weather environments. This sort of testing is common in the automotive world, where early cars are sent to extreme environments to ensure they can operate in the worst conditions. Astra incorporated those lessons and got back to a cold weather site with LV0009 and while lightning concerns prevented them from launching on the first day of the window for LV0009, they returned to the pad the next day, had a clean launch count, and launched right on time in the first minute of the window. As Astra works to scale its operations, it will continue to test in extreme conditions. These exact examples can be seen clearly in the chart provided by Astra showing the improvement through past and recent launches. Astra finished this progress report by saying, “We are proud of our team for the progress that has been made and we continue to focus on delivering access to space at scale. While we have demonstrated a shorter return to the pad with LV0009, we may increase time between launches to prepare for our new launch system or due to other conditions outside our control, including availability of launch dates at our spaceports.” Its clear Astra has made very significant progress in recent years and is working to improve all aspects of the company.

Astra Spacecraft Engines

In other Astra news, the company has signed another contract, this time with LeoStella. On April 12th, Astra tweeted saying, “Astra announces contract for Astra Spacecraft Engines with @LeoStellaLLC.” Specifically, they announced a contract for Astra to provide multiple Astra Spacecraft Engines for LeoStella satellites. Astra is expected to begin delivering the propulsion systems later this year and into 2023. LeoStella designs and manufactures operational satellites cost effectively and at scale. Astra’s Spacecraft Engine has demonstrated that it can assist satellites in achieving and maintaining target orbits and maneuverability and is expected to be integrated onto a variety of LeoStella’s satellites. “As demand for small satellites continues to grow, we are always looking for innovative options to provide highly efficient, reliable propulsion for our satellites,” said Tod Byquist, Director of Programs and Supply Chain at LeoStella. “Astra’s Spacecraft Engine has good flight heritage and the performance we need to get our satellites to space on schedule.” “LeoStella is a pioneering force in constructing critical space infrastructure through a variety of satellite designs,” said Mike Cassidy, VP of Product Management at Astra. “Their vision to deploy reliable, cost-effective satellites aligns closely with Astra’s and demonstrates the innovative forces at work to expand and accelerate access to space.”

Taking a closer look at Astra’s spacecraft engines, the company has quite a bit to offer. This includes ASE (Astra Spacecraft Engine) & ASE MAX, which can be configured with multiple thrusters and PPUs to handle a wide range of missions, from the smallest Earth observation satellites with 100W Orbit Average Power, up to large communication satellites with multiple kilowatts of solar power. With multiple thrusters, LEO-GEO orbit raises can take as few as 12 weeks. Specifically, ASE and ASE Max include an instant-start center-mounted cathode and compact design. Each thruster leverages the past 50 years of Hall thruster research in an efficient, clean sheet design. In addition, the PPU (Power Processing Unit) is radiation hardened by design, replacing many microprocessors with simple and reliable components – creating a single circuit board design that is 95% efficient. Lastly, propellant tanks are sized specifically to fit the unique requirements of each customer mission with flight-proven COPV construction rated to 2,700 psi or 4,000 psi. It’s clear Astra has put a lot of focus not only on its launch vehicle and progress but on other valuable aspects of the space industry including spacecraft engines and more.

Conclusion

There are many different factors that determine the success of a rocket company. Astra knows this and has been working very hard over the past few years to improve. This not only includes ensuring the rocket reaches orbit, but also making sure the time in between launches is minimized as much as possible. The more frequently and consistently you can launch means much greater opportunities for the company down the line. We will have to wait and see how Astra progresses and the impact it has on the space industry.