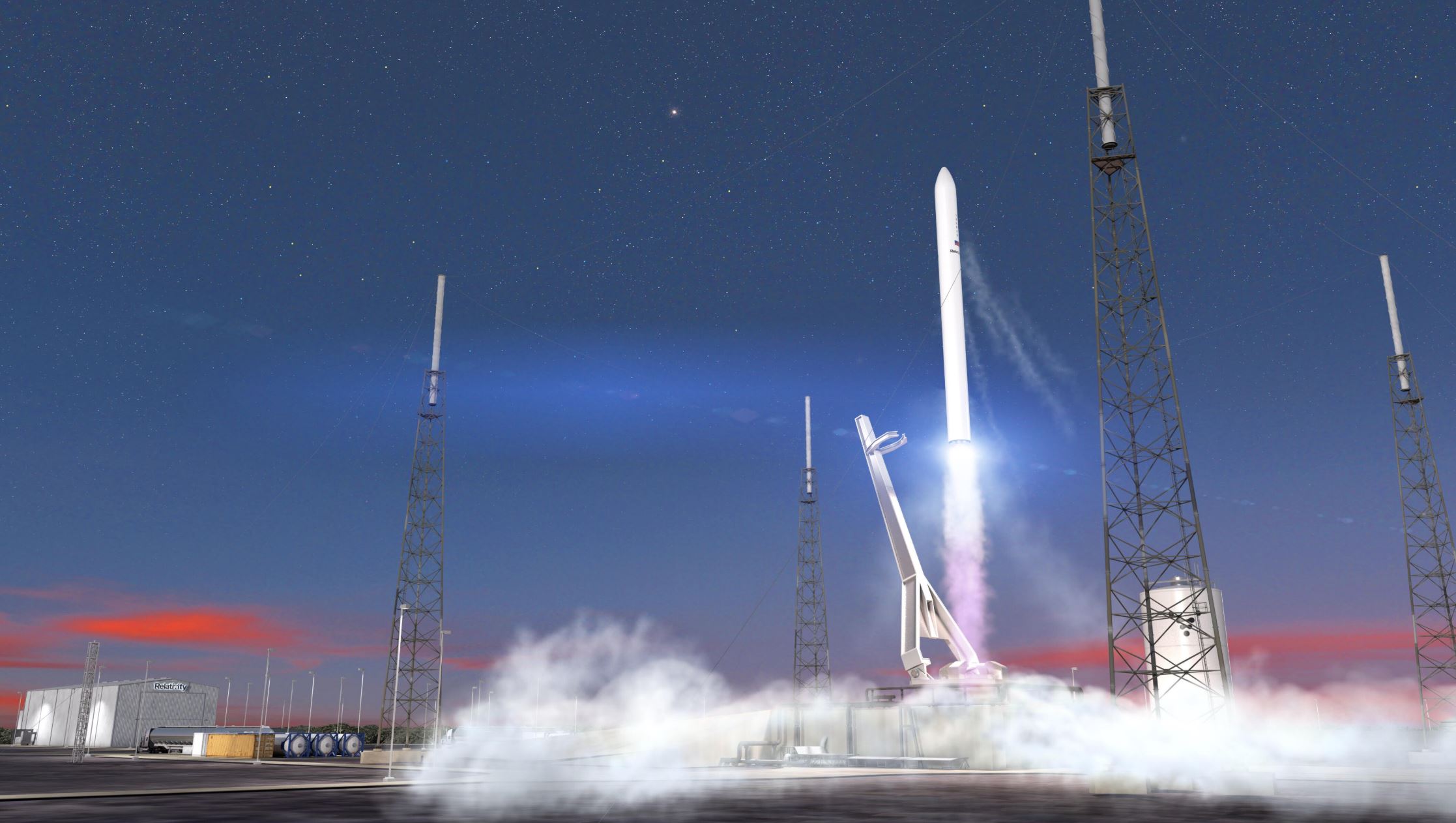

A Closer Look At Relativity Space’s Terran 1 Launch Vehicle

With the small satellite market continuing to grow faster than ever before, companies including Relativity are hard at work on future small-lift launch vehicles. These are meant to be efficient, affordable, and help fill some of the large demand for launching small satellites and other cargo. Specifically, Relativity is working on not only the Terran R but also the Terran 1.

Relativity Space’s Terran 1 launch vehicle is meant to expand the companies capabilities. It does this with an impressive design featuring Aeon engines, quality performance, and a unique build. All of which combine into a single launch vehicle with many capabilities and applications for the future. This includes small satellite, constellation deployment, and more.

While Relativity Space is a somewhat new company they are making great progress in many different sectors. This not only includes rocket development but the factory and manufacturing process as well. The approach is very different from a lot of other companies and agencies but could end up paying off in the future. The success of Terran 1 will provide evidence to the future outlook of Relativity Space as a company and their projects.

Terran 1 Overview

Terran 1 is a two-stage expendable launch vehicle powered by liquid natural gas or LNG and liquid oxygen. Relativity is confident that “Terran 1 is the most innovative product to emerge from the aerospace manufacturing industry since the dawn of privatization of space 20 years ago.” This rocket is designed to provide customers with the most responsive and affordable small satellite launch service on the market. Terran 1 is designed to provide a predictable and controlled launch environment allowing for simplified payload design requirements. Terran 1 can support both industry-standard and custom interfaces, using commercially available adapter and separation hardware in addition to mission-specific designs. Environmental control systems also ensure to maintain clean, thermally controlled payload environments.

Terran 1 comes in at 35m tall and 2.3m in diameter. It uses 10 Aeon engines with 9 on the first stage and 1 Aeon vacuum on the second. Relativity Space prints all structures and major engine components using proprietary printable metal alloys. This leads to a dramatically simplified manufacturing process when compared to traditional fabrication methods. This is another aspect that makes the Terran 1 so unique. Additionally, Terran 1’s fairing volume accommodates a variety of payload designs and configurations, including dedicated launch for single payloads and constellations as well as multi-manifest and rideshare configurations. All of these features work towards the goal of fast and affordable launches for small satellites and constellations. Relativity has been working hard on Terran 1 and are aiming for a first launch attempt around the middle of 2022.

Terran 1 Features

Performance – The first important aspect of the Terran 1 I want to point out is the launch vehicle’s performance and capabilities. Terran 1 provides direct-injection and multi-burn launch services to a variety of target orbits, delivering as much as 1,500 kg into orbit. Relativity points out that the launch vehicle can carry 1,250 kg to low Earth orbit and 900 kg to SSO. This makes the Terran 1 a great option for a lot of companies within the small satellite market. The cost for a dedicated mission is $12 million. While this is still a lot of money, it is quite competitive within the small-lift launch vehicle market. Prior to launching, Relativity selects which launch site supports each mission based on customer-specified orbit requirements.

Terran 1 is built for high injection accuracy, and its standard mission design includes trajectory and separation analyses as well as collision avoidance maneuvers and deorbit as required. It also is capable of delivering payloads into elliptical orbits. Customers can contact Relativity for the potential use of Terran 1 along with its in-space transportation partners for insertions beyond the dropoffs shown by Relativity.

Build – The next feature of Terran 1 that makes it stand out is the build. Starting at the top you have the fairings. These are 6.8 m tall and 3 m in diameter. Below the fairings is the second stage which is 8.1 m tall. This stage consists of a liquid oxygen tank at the top with a liquid natural gas tank right below. At the bottom of the stage is a single vacuum optimized Aeon engine. This engine produces over 28,000 pounds of force in the vacuum of space. The second stage has additional features such as an engine restart capability, and a cold gas reaction control system. This stage is autogenously pressurized including integrally printed tanks with a common dome. Lastly, the second stage’s payload controller offers separation initiation, separation detection, ethernet and serial in-flight payload telemetry channels. Pitch and yaw control is provided by electro-mechanical thrust vector control actuators affixed to the Aeon Vacuum engine.

Next up on the Terran 1 launch vehicle is the first stage. At the top is the interstage helping connect the first and second stage together. The interstage is printed with a stage separation system including pneumatic pushers. The first stage is 24.3 m tall and has similar features to the second stage. At the top is a larger liquid oxygen tank with a liquid natural gas tank below. You then have 9 Aeon engines at the bottom providing practically all the power for Terran 1. Specifically, each of these 9 engines produces 23,000 pounds of force at sea level. This combines to a total thrust at liftoff of 207,000 pounds of force. This stage also features an autonomous flight safety system and is autogenously pressurised. The material used for the majority of the components I mentioned is a proprietary printable aluminium alloy.

Aeon Engines – The last aspect of Terran 1 that I want to mention are the Aeon engines. These engines are unique for many reasons including their power and how they are manufactured. Relativity’s Aeon engines are designed, assembled and tested in house. Except for the second-stage nozzle extension, each of Terran 1’s 10 engines is based on a common design. This enables simplified and repeatable manufacturing and acceptance testing. As I mentioned prior these engines are fueled by liquid oxygen and liquid natural gas. Aeon engines use these propellants along with a gas generator engine cycle. Each engine uses two turbopump assemblies for thrust and mixture ratio control. This includes one for liquid natural gas and one for liquid oxygen. Additionally, the thrust chamber is regeneratively cooled with liquid natural gas, which is then injected into the main combustion chamber and burned with liquid oxygen to produce the required thrust. Over time Relativity has continued to work hard on the development and manufacturing process of their rocket engines. The company has many different tests stands and other infrastructure in place helping test, create, and use these engines.

Conclusion

With the continued growth of the small satellite market, a large list of companies is working on next-generation small-lift launch vehicles meant to fill the increasing demand. Relativity Space is one of these companies developing a launch vehicle with some unique plans and features. Some of these aspects include the performance, overall build, and Aeon engines. All of which work together and are meant to provide a one of a kind small-lift launch vehicle of the future. There is quite a lot of competition within the small-lift launch vehicle market however Relativity Space is very confident. They are doing a lot of things differently when building Terran 1 that could end up paying off is successful. With a first launch planned to happen around the middle of 2022, we will have to wait and see how Terran 1 progresses and the impact it has on the space industry.