Exactly What Went Wrong On Astra’s Most Recent Launch

It is an extremely difficult process to successfully launch a rocket. This especially is the case for companies working to get some of their first launches under their belt. Even large agencies struggle to get rockets into low Earth orbit in one piece. Not long ago Astra attempted another launch with its LV0008 launch vehicle. It did not go to plan unfortunately and Astra just recently figured out exactly why.

Around one month ago on February 10th, Astra attempted another launch of its rocket. At first, everything worked as intended up until stage separation when the stages struggled to release before violently separating from each other. Just yesterday Astra released some information regarding the report highlighting exactly what went wrong. Specifically, the separation mechanisms apart of the fairing were fired in an incorrect order causing the mission to fail.

In order for a launch to be successful, each of the countless parts has to work perfectly and in symphony. If even just one component of the launch vehicle misfires or fails to deploy, it can end up sacrificing the entire launch. Something similar seems to have been the case for the most recent Astra launch. Here I will go more in-depth into what exactly caused the error and what Astra found in their investigation.

Astra Findings

In late 2021, Astra launched for the 6th time with LV0007. This mission was the company’s first fully successful launch and marked a great milestone for Astra. Months later on February 10th, Astra attempted the company’s 7th launch with LV0008. Looking at the video of the launch it’s clear to see where something went wrong. Everything went according to plan based on the footage up until around 3 minutes in. Here you can hear the MECO call, followed by two jolts seen from the cameras within the fairings. Then at 3 minutes and 11 seconds into the launch, both stages violently separate causing the second stage to spin out of control before the video is cut off. This footage suggested that there was an error related to either stage or fairing separation. Thankfully Astra just released information regarding what went wrong on the most recent mission. Yesterday on March 7th, Astra tweeted saying, “Post-Launch Investigation: What We Found and Next Steps.” This tweet provided a link to Astra’s post-launch investigation where they are confident the issue has been found and solved.

They first point out that “On February 10, 2022, we launched Launch Vehicle 0008 (LV0008). This was our first launch with a deployable customer payload and our first time launching from Cape Canaveral. After a nominal first stage flight, an anomaly occurred during the stage separation process which resulted in the upper stage not reaching orbit and the end of the mission. We immediately initiated our investigation process to determine the root cause of the anomaly. Now, we can share more about what we’ve learned to date.” Astra’s investigation verified that the payload fairing did not fully deploy prior to upper stage ignition due to an electrical issue. The separation mechanisms (our fairing has 5 of these) were fired in an incorrect order, which resulted in off-nominal movement of the fairing that caused an electrical disconnection. Due to the disconnection, the last separation mechanism never received its command to open, which prevented the fairing from separating completely before upper stage ignition. They also discovered a software issue that resulted in the upper stage engine being unable to use its Thrust Vector Control system. This led to the vehicle tumbling after the off-nominal stage separation, and caused the end of the mission.

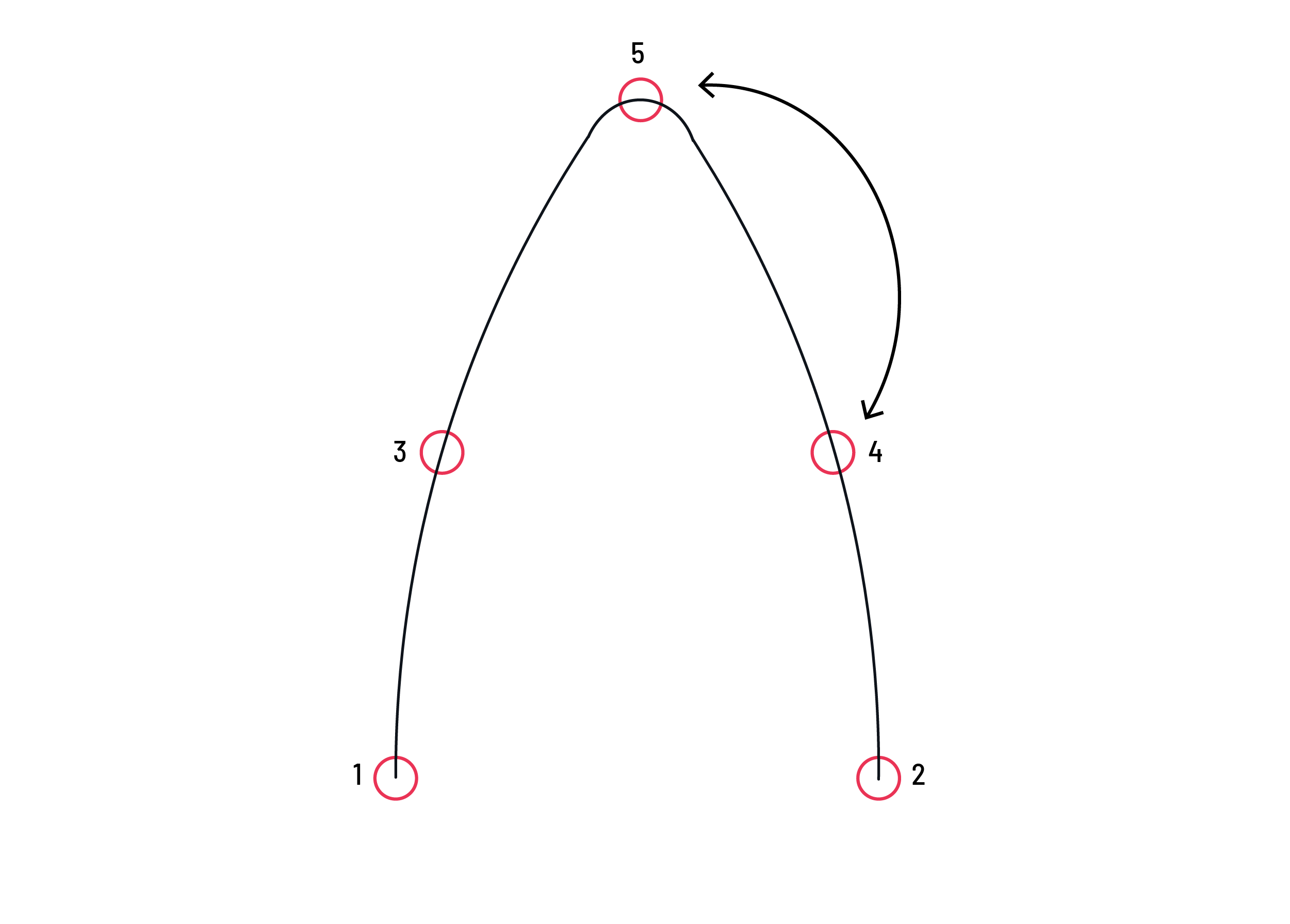

Astra went more in-depth into the problem and determined exactly what went wrong. The root cause of the fairing separation issue was an error in an electrical harness engineering drawing. This harness was built and installed onto the vehicle exactly as specified by our procedures and the engineering drawing, but the drawing error led to two harness channels (locations ‘4’ and ‘5’) being swapped. Prior to the LV0008 flight, Astra had conducted an end-of-line signal test to verify the separation system and ensure that the system was wired correctly. This test would have been able to detect an error in the harness build or installation, but it was unable to detect an error in the design. The swapped separation channels caused a different deployment sequence than we expected, and this led to the failure to open the fairing. Astra has been able to recreate the failure mode by conducting several experiments at its factory with real flight hardware, one of the benefits of having an active production floor with several launch vehicles in various states of production at the same time. In addition, after determining the root cause of the software issue, they found that the flight control software was vulnerable to a specific “packet loss” failure mode. A missed series of signals resulted in a chain of events, resulting in the upper stage’s inability to recover from its tumble. Although Astra had designed its software suite to be resilient to packet loss, an unlikely combination of factors caused a failure that we didn’t predict. Astra has been able to use its hardware-in-the-loop simulator to step through exactly what happened and diagnose the root cause with high confidence.

Astra went on to mention how they fixed the problem. Specifically, through the investigation process, they had identified two problems that needed fixing: the harness issue and the software issue. Soon after discovering the harness drawing error, Astra fixed the drawing and incorporated the change on previously built harnesses. They also implemented a new end-of-line signal test that will allow us to identify this class of issue in the future, if it were to occur, prior to launch. On the software side, they have introduced a trio of upgrades designed to make the system even more resilient to packet loss and other similar failure modes. Through constant iteration and extensive testing, Astra has been able to demonstrate that the changes eliminate the failure mode we saw on LV0008, while making the software suite much more robust. Astra finished the report by highlighting that “Here at Astra, iteration and learning are core parts of our culture. I’ve been continuously impressed with the speed, passion, and diligence that the team showed as they worked through these complex issues to identify exactly what occurred and determine the right path forward to resolve each problem. With the root causes identified and corrective measures in place, we’re preparing to return to the launch pad with LV0009 soon — stay tuned!” While this launch did not go as planned, Astra has learned a lot from it and are preparing for the next mission.

Conclusion

Rocket launches are extremely complex and difficult things to do. It comprises hundreds of different components and steps that each need to work perfectly in order for the mission to be a success. Astra’s most recent launch failed due to the fairings. Specifically, a drawing error caused the fairings to not be properly deployed. This in return sent the upper stage out of control. Astra however has learned what went wrong, how to fix it, and is moving on to the next launch. We will have to wait and see how Astra progresses and the impact it has on the space industry.